The role of the “Forward March” in food safety

12 February 2024

The role of the “Forward March” in food safety

Your kitchen is the heart of your establishment! It's essential to build it in a thoughtful way that respects food safety standards. With this in mind, Atelier du Chef is committed to the fundamental “Marche en avant” principle. Why is this principle essential, and how do we apply it to each one of our projects? Let's find out!

What is the “forward march” in a professional kitchen?

Codified in the HACCP system, originally created for NASA, the forward march principle imposes an organization of premises and work that guarantees a certain level of food safety, by avoiding possible cross-contamination.

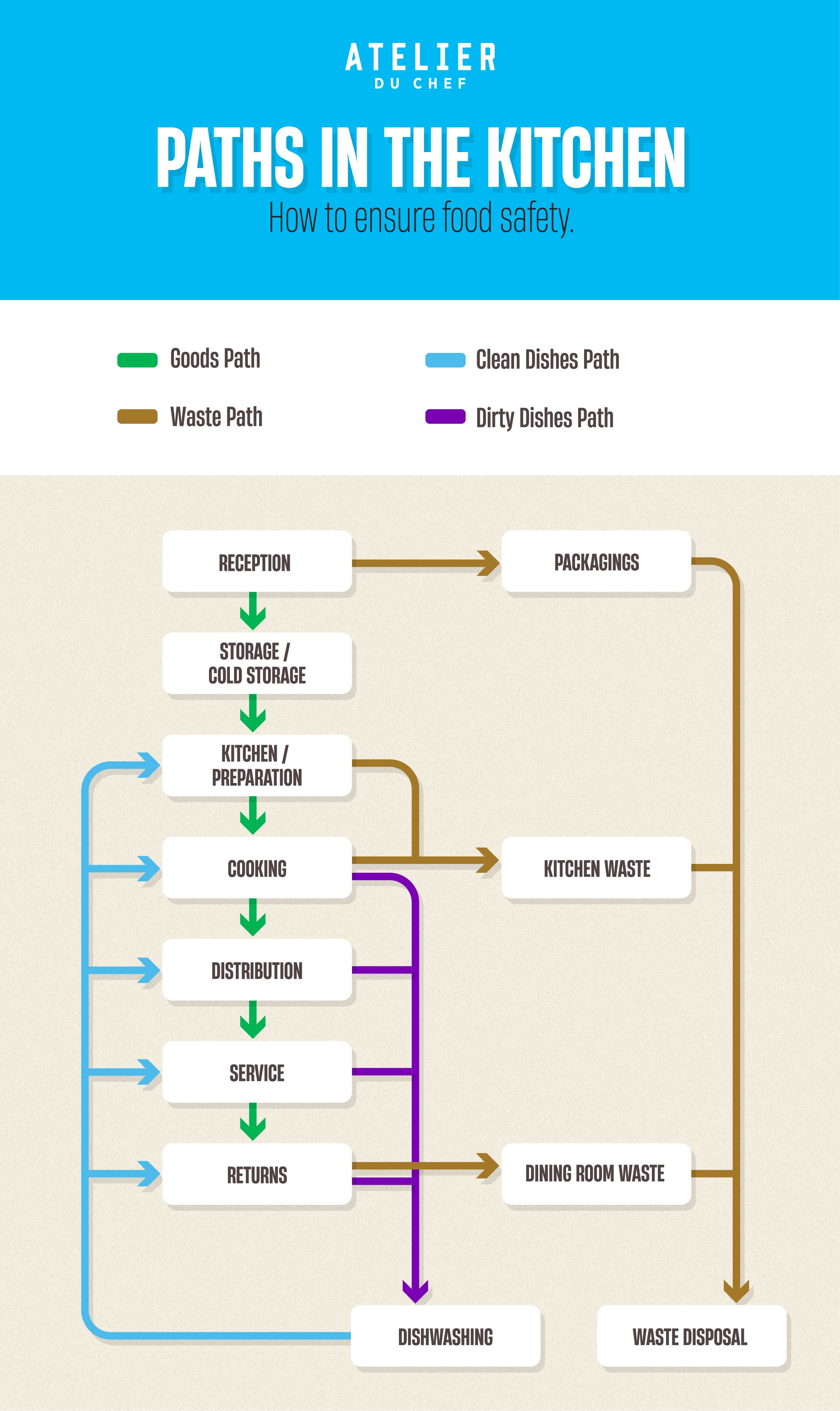

Separate circuits must be set up for food, water, and waste. Clean and dirty must never cross paths!

In new projects, providing sufficient space to set up organized flows is usually possible, thus avoiding any undesirable crossovers. However, in smaller structures where space may be limited, it is sometimes necessary to plan a forward march in time, organizing the different stages of preparation in the same space.

The kitchen plans we design at l'Atelier du Chef all respect this fundamental principle of forward planning, to offer you a kitchen that complies with food safety standards, as well as optimized workstations.

Example of a "perfect" plan that respects the forward march for better

food safety.

How does Atelier du Chef implement the Forward March in all your projects?

All of our plans are designed to optimize the working time of food service staff and the flow of traffic in your professional kitchen. The clean and dirty circuits never cross:

1. The reception area

Located outside the kitchen, this is where all products are handled (packaging is removed and discarded). This buffer zone reduces contaminants from the outside and prevents harmful elements from entering the kitchen.

2. The storage area/cold room

This area is reserved exclusively for clean, packaged foods (e.g., meat, packaged animal products, dairy products, prepared sauces, etc.). It is equipped with shelves and all the necessary tableware for optimal product storage. Opened foodstuffs and pre-cooked preparations are kept in airtight storage containers.

3 The cooking/processing area

Strictly dedicated to clean food, this area is separated into two zones, one for handling raw food and the other for cooked food, thus avoiding cross-contamination. These usually includes a food processor, a mixer, a slicer, a vacuum machine and so on.

The preparation utensils used cannot be shared between the two areas. All products leaving the kitchen area are considered clean products.

4. The cooking area

All processed foods are cooked here. Cooking equipment such as fryers, ranges, griddles, grills, combi ovens, etc. are located in this area.

5. Distribution area

This area is dedicated to the storage of cooked food waiting to be served, as well as the setting up of plates. Warmers are typically installed here to keep cooked food at the right temperature.

6. Service area

This area separates the kitchen from the dining room. Serving staff never enter the clean zone, and have access to the plates to be served via a pass-through. There are also refrigerators for desserts or condiments, freezers for ice cream, a microwave, etc.

Atelier du Chef makes it a point of honor to provide you with the most ergonomic kitchen plans, in compliance with the strictest food safety standards, to create the productive and healthy workplace your establishment deserves.

Post Comments

You must be logged in to post a comment.

Click here to log in